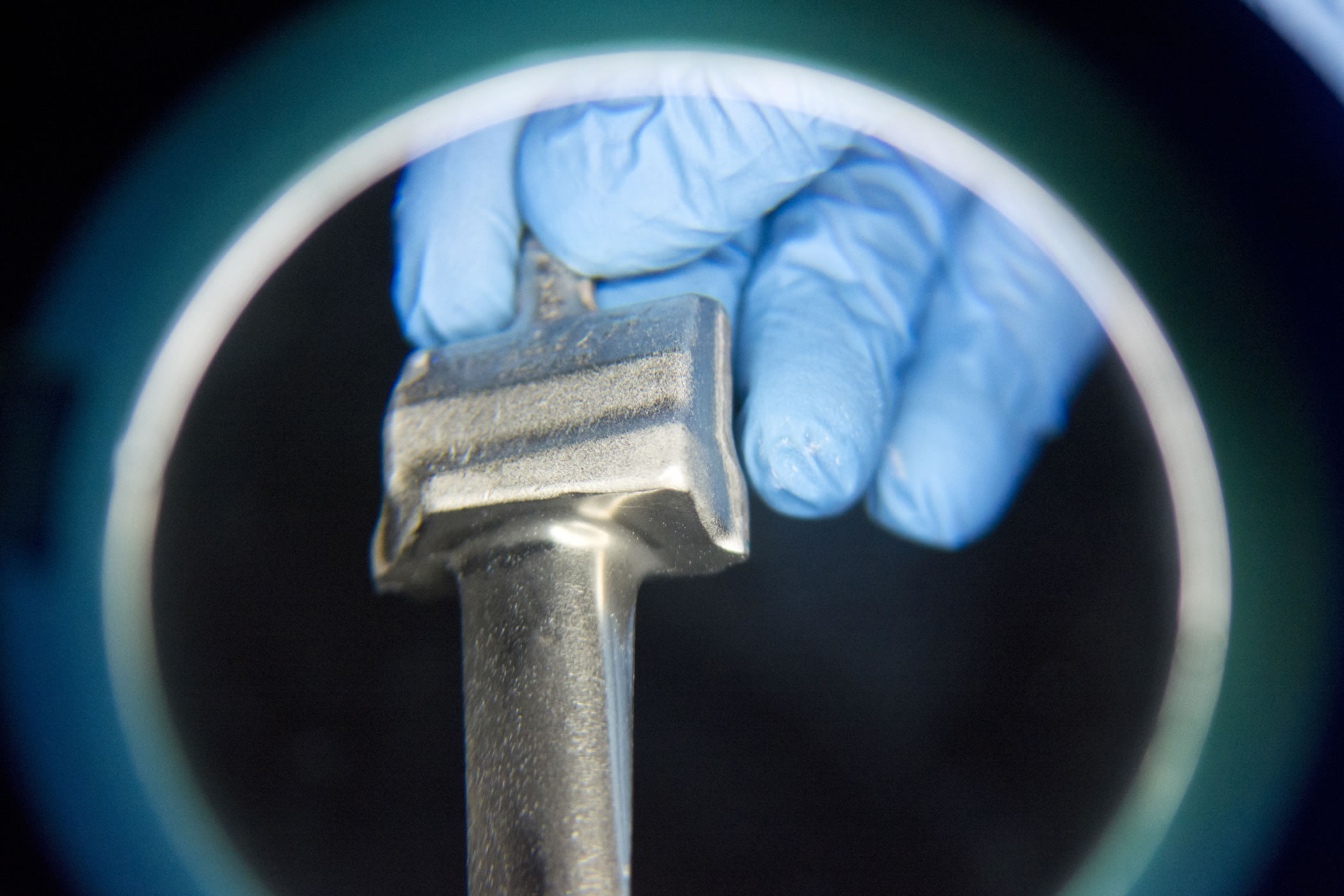

NDT, Mechanical and Metallurgical Inspection

We have our own modern purpose built test laboratory and its team of skilled technicians and operators test material we produce to ensure strict compliance to customer requirements. Opened in 2016, the facility helps reduce lead times as all test samples, testing, and certification are fully integrated on site.

The laboratory has the capability to perform mechanical tensile and impact testing over a range of temperatures and provide a comprehensive range of metallurgical assessments, included as part of customer product certification.

NDT inspection (AS9100)

- Operators qualified and certified to SNT-TC-1A, PCN and NAS 410 Level II

- UT

- LPI

- MPI

- VT

- Contact ultrasonic examination of forged and machined products using contact probes

- Positive material identification testing to indicate the chemical analysis of alloys

- Fluorescent dye and visible penetrant inspection of forged and machined products

- Fluorescent and visible magnetic particle inspection of forged and machined products

- Experienced visual examination of finished products

- CMM dimensional characterisation on components up to 600mm diameter

- Component marking using fully programmable dot marking machine

Mechanical testing (ISO 17025)

- Tensile Testing (Ambient – 800°C)

- Stress Rupture (600 – 1000°C)

- Charpy (V-notch) Impact (-80 – 200 °C)

- Rockwell Hardness (HRC & HRB)

- Vickers Hardness (HV10 & HV30)

- Brinell Hardness (HBW 10/3000)

Metallurgical testing (ISO 17025)

- Microstructure

- Macrostructure

- Grain Size (Comparison & Intercept Methods)

- Volume Fraction

Nadcap Specific Tests/Methods (AC7101)

- Specimen Heat Treatment (350 – 1130°C)

- Alpha Case Depth Measurement